SV120

Read the details

SV120

For one of the larger models in our range of midi excavators, the compactness and short tail of the SV120 mean its still suitable for small sites. A smart control system includes fingertip operation, while a dozer blade with rounded profile improves material removal. Four independent hydraulic circuits mean it can use a wide range of attachments. The powerful, low-consumption and eco-friendly engine meets the latest EU and EPA regulations, and offers two-speed travel drive with automatic and rapid shifting.

COMPACTNESS

The SV120 closes the gap between mini and large excavators. As an 11.3 to 12.5 ton machine, it’s just as capable, easy to control and comfortably equipped as its bigger counterparts. It also boasts all of the advantages of a compact design, including a short rear end. This makes it the right choice for a wide variety of tasks, including city construction sites, road building, and handling bulky and heavy materials.

IMPROVED POWERLINE

The SV120 midi excavator is powered by an engine which conforms with EU Stage IV / EPA Tier 4 Final regulations. Exhaust gas after treatment reduces pollutants by up to 90%, including nitrogen oxide, hydrocarbons and particulate matter. We achieve this, not with a particulate filter, but via an improved combustion and injection system and a diesel oxidation catalytic converter. The optional auto deceleration system means that in the event of inactivity, the engine switches to idle speed, thus saving fuel, reducing emissions and lowering operating costs.

ADVANCED HYDRAULICS

Thanks to the four independent hydraulic circuits, the SV120 increases the range of attachment tools it can use. The hydraulic pump provides a delivery rate of approximately 120 l/min to power them. The driver controls a tilt-rotator with hydraulic quick-hitch system plus a hydraulically powered tool such as a sorting grab, asphalt cutter or rotary cutter. The control circuits don’t influence each other, so all working cycles and functions can be operated simultaneously and independently. Due to the servo-assisted controls, working cycles are smooth, comfortable and highly productive.

INNOVATIVE UNDERCARRIAGE

A well designed undercarriage is the foundation for success – that of the SV120 is characterised by its extremely robust design, high level of stability, powerful driving characteristics and individual configurations to match the task at hand. The rounded form of the dozer blade provides excellent material movement during levelling work, and its extra width perfectly matches that of the tracks. Work with the bucket can thus be done directly against the blade – useful in tasks such as cleaning the site. The optional float position delivers additional support.

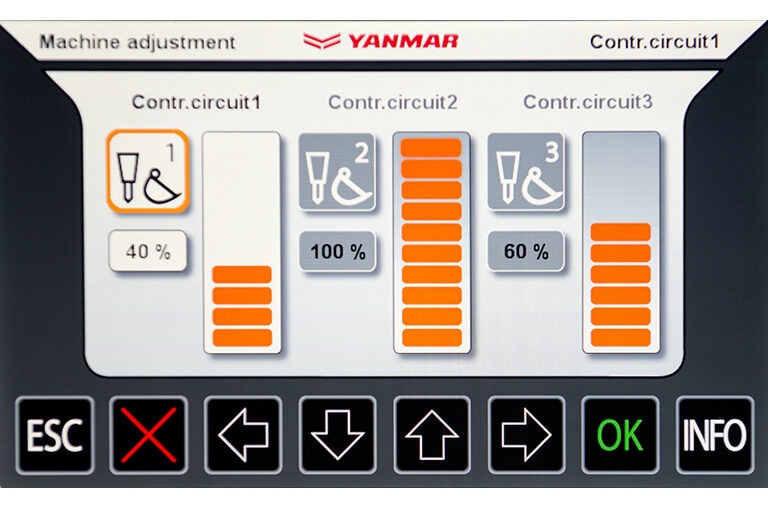

SMART CONTROL

A smart control system lets the driver determine the optimum excavator power for different applications, minimising lost energy and time. In particular, hydraulic control circuits can be operated quickly. The delivery rates of these circuits are adjusted on a percentage basis via the bar graph depending on the application and work attachment, even during continuous operation. Other useful functions include eco mode, activated at the touch of a button, and climate control, whereby the heating and defrosting functions can be adjusted precisely to the desired conditions. Automatic air conditioning is also available as an optional extra.

FINGERTIP CONTROL

With the fingertip control system via a thumbwheel on the left joystick, electro-proportional operation of the advanced hydraulic functions is particularly simple. The operator can meter the oil flow from zero all the way to full with extreme precision, which makes it easier to actuate attachments such as a clamshell bucket, swing bucket or sweeper. This increases productivity while also lowering operator fatigue.

REAR VIEW CAMERA

The SV120 offers good all-round vision, but is additionally equipped as standard with a rear-view camera. This not only allows for more safer reversing on busy sites, but also gives an enhanced view of the situation when rotating the machine. An optional reversing camera is also available, with data displayed in a clear smartphone style arrangement on the anti-reflective 7-inch central display screen.

TAILORED FOR YOUR JOB

Yanmar offers numerous equipment options to help increase productivity on specific tasks while reducing wear and damage. Boom choices include monobloc for ultra-fast operation and heavy loads, and two-piece articulated booms for outstanding vertical digging depth and greater discharge heights. Both can be used with dippersticks of varying lengths for greater reach. Track options to suit different terrains include rubber, standard steel and wide steel, while a combined Roadliner track is proven on many types of ground. Only rubber-coated steel plates have to be changed when worn – not the entire track. Blade choices include float position and extra-wide 2,800 mm option.