ViO57-6B

Read the details

ViO57-6B

The advanced engine of the ViO57-6B meets all EU emission requirements, with electronic controls offering real precision power as well as first-rate fuel economy. A ViPPS hydraulic system co-ordinates performance, while automatic two-speed drive motors add further automatic precision and increase ease of operation. This zero tail machine also features an improved undercarriage, resulting in exceptional stability and durability, together with greater safety and operator comfort. Simple to maintain, optional SmartAssist Remote makes this machine straightforward to manage as well.

COMPACTNESS

This is a true zero tail swing machine, as neither the counterweight nor the front part of the upper frame project beyond the track width. With its front part designed not to protrude, the ViO57-6B also has a very small turning radius. The rear blind spot is additionally reduced to a minimum. All of this results in improved safety for both the operator and on-site workers. It also makes this model ideal for constricted urban environments and when working along walls.

CLEAN STAGE V ENGINE

The advanced 28.3 kW TNV engine meets all EU Stage V emission requirements, thanks to cooled exhaust gas recirculation (EGR) which reduces drastically nitrogen oxide emissions, and a diesel particulate filter (DPF) that ensures cleaner exhaust emissions. Other eco-friendly features include direct injection for cleaner burning power, with a common rail system that allows for fine-tuned electronic control. In addition, an exclusive regeneration system combats clogging and reduces cleaning down-time.

ELECTRONIC ENGINE

Full electronic control gives the engine intelligent power and manoeuvrability, with drive motors automatically shifting up or down depending upon the effort required. The operator is thereby provided with the best solution in terms of speed or pushing force, making operation easier. Extra fuel economy comes from the eco-mode function, which reduces motor speed by 300 rpm, thereby reducing fuel consumption. If the operator doesn’t touch the operating levers for four seconds, the engine drops back to idle. This also results in less noise and fewer emissions.

SMOOTH AND SIMULTANEOUS MOVEMENT

The ViO57-6B uses a ViPPS hydraulic system, which ensures smooth and co-ordinated performance across all operations, even while travelling. The system features two gear pumps and a double variable displacement piston pump. These three main pumps totalise a maximum flow of 139.4 l/min, available for main machine operating movements. The pump flows are cumulated in the main control valves to obtain the optimal combination of speed, power, smoothness and balance.

EASY OPERATION

The automatic two-speed drive motors shift automatically up and down depending upon the effort required. This instantly provides the best solution in terms of speed or pushing force, making operation easier. An auxiliary hydraulic circuit is also standard equipment on the ViO57-6B. This is operated via a proportional control function located on the joystick which adapts the course and direction of the oil flow. An easy-to-operate potentiometer further adjusts the oil flow to the optimal requirement for each attachment. In addition, a drive motor develops 10% more torque, improving cycle times and productivity, especially in levelling applications.

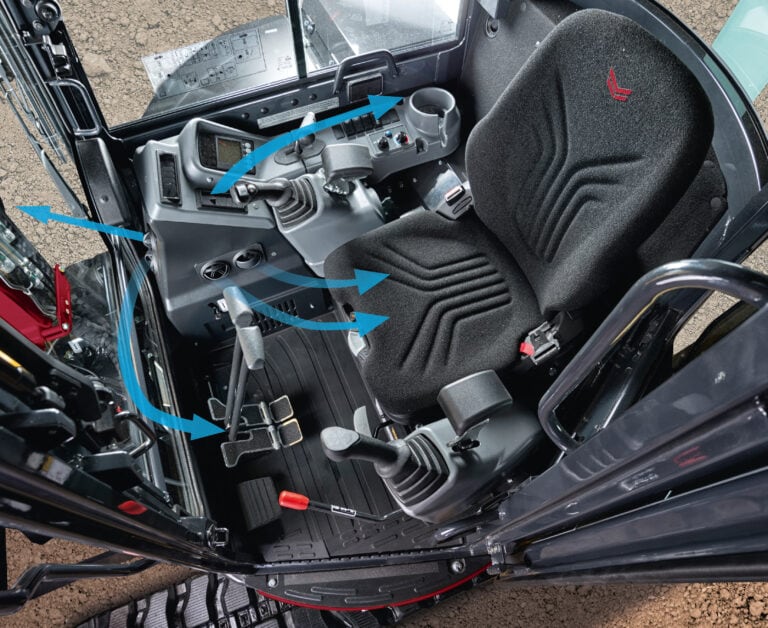

EXTRA COMFORT

The large cabin offers high levels of comfort, including a generously sized entrance door and plenty of interior legroom. A translation lever with folding pedals also adds further space and comfort for the operator. Welcome extra touches include an adjustable wrist rest, and the seat features pneumatic suspension. The ergonomic operating environment has also been designed to reduce noise and thus operator fatigue. Three rear-view mirrors ensure excellent all-round operational visibility as well.

IMPROVED STABILITY

The X-shaped box-section structure of the undercarriage provides excellent torsional stiffness, with the frame designed for maximum durability. All the components of the undercarriage have been upgraded to increase durability and service life of the machine and reduce its total cost of ownership. Specific upgrades include increase of the idler width by 25%, expansion of the track rollers diameter by 14% and width by 13%, and increase of the sprocket width by 29%. This new undercarriage design and an optimised mass distribution contribute to improving the overall stability of the ViO57-6B.

EASY MAINTENANCE

The ViO57-6B can be used for long periods between services. It’s equipped with a digital interface which informs the operator in real time about the status of the machine and assists with scheduling servicing. Daily maintenance is made easy thanks to the easy-to-open engine bonnet and the single-hinge mounting of the right-hand side cover. This gives access to all major elements that may need regular checking, including the fuel tank, radiator, air filter and several other components. A flat floor mat also makes cleaning easier.